What is meant by quality (QC) inspection?

Quality Control (QC) inspection is an appraisal process that compares goods or services to a standard.

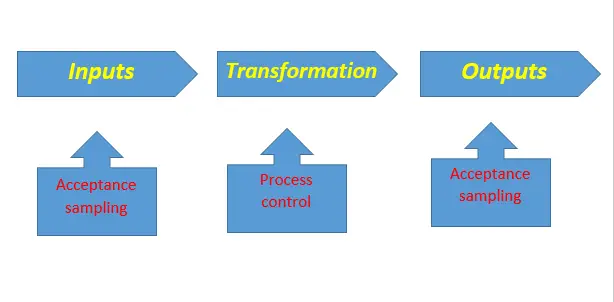

The common sense of checking conformance earlier than production is to make certain that inputs are acceptable.

The common sense of checking conformance at some stage in manufacturing is to ensure that the conversion of inputs into outputs is processing in an appropriate way.

The logic of checking conformance of outputs to make a very last verification of conformance earlier than passing goods directly to clients.

To determine whether a process is functioning as intended or to confirm that a batch or lot of raw materials or very last products does no longer include more than a specified percentage of faulty items, it is important to physically study at the least some of the goods in question.

The purpose of QC inspection is to offer records in a form at the degree to which items conform to a standard. The basic issues are:

- How much to inspect in the process inspection should occur?

- At what points in the process inspection should occur?

- Whether to inspect in a centralised or on-site location?

- Whether to inspect attributes (i.e., count the number of times something occurs) or variables (i.e., measure the value of a characteristic)?

Consider, for example, QC inspection at an intermediate step in the manufacture of personal computers.

Because inspection costs are often significant, question natural arise on whether one needs to inspect every computer or whether a small sample of computers will suffice.

Moreover, although QC inspections could be made at numerous points in the production process, it is not general cost-effective to make QC inspections at every point.

Hence the question comes up of which points should be designed for inspections.

Once these points have been identified, a manager must decide whether to remove the computers from the line and take them to a lab, where specialized equipment might be available to perform the certain test, or to test them where they are being made.

Thus QC inspection is a vital point in manufacturing which should be considered meticulously in supply chain flow.

Follow our later posts for detail discussion on these points and QC inspection guidelines.

This is very attention-grabbing, You are an overly professional blogger.

I’ve joined your feed and stay up for seeking extra of your magnificent post.

Also, I have shared your site in my social networks