Importance of supply chain flows

There is a close connection between the design and management of supply chain flows (product, records, and cash) and the fulfillment of a supply chain.

McDonald’s supply chain flow chart can be discussed here, but another giant Dell PC is an example of a company that has successfully used precise supply chain practices to help its competitive strategy have been shown here for a case study. Maximum e-business failures also can be attributed to issues with the design and control of supply chain flows.

A Case Study

Dell has, over a particularly quick period, come to be the arena’s largest computer manufacturer. They have got generated margins, income, and in the end, marketplace capitalization past any in their competitors’ laptop enterprise.

Supply chain management processes followed

Dell has attributed a good-sized part of its achievement to the manner it manages flows-product, records, and money inside its supply chain diagram.

Dell’s primary supply chain model is direct sales to clients. As distributors and retailers are bypassed, the Dell supply chain flow has most effective three ranges-clients, producers, and suppliers. Due to the fact Dell is in direct touch with its customers, it’s been able to finely phase them and analyze the needs and profitability of each segment.

Dell’s primary supply chain model is direct sales to clients. As distributors and retailers are bypassed, the Dell supply chain flow has most effective three ranges-clients, producers, and suppliers. Due to the fact Dell is in direct touch with its customers, it’s been able to finely phase them and analyze the needs and profitability of each segment.

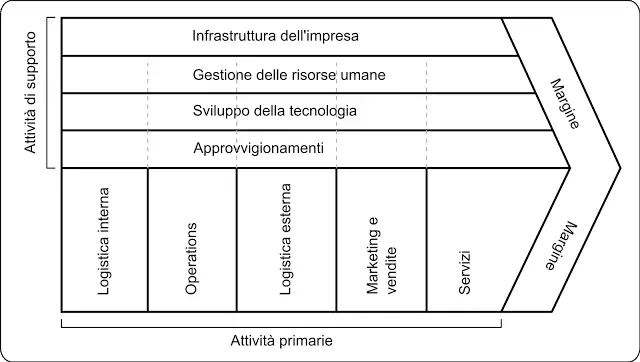

Value chain model

Close contact with their customers and information of clients’ wishes also allows Dell to broaden better forecasts. To similarly enhance the suit between supply and demand.

Dell makes a lively effort to steer clients in real-time, on the phone or via the net, towards PC configurations that may be built given components available.

At the operational aspect, stock turnover is a key overall performance measure that Dell watches very closely. Dell consists of less than ten days’ well worth of stock; in the evaluation, the competition, selling thru shops, consists of within the vicinity of eighty to one hundred days’ worth of stock.

Value chain analysis

If Intel introduces a brand new chip, the low level of inventory permits Dell to visit the marketplace with a laptop containing the chip quicker than the competitors.

If costs all of the sudden drops, as they regularly do, Dell has less stock that loses value about its competitors.

For a few merchandises, along with Monitors via Sony, Dell continues no stock. The transportation organization, correct selections up the right range of computer systems, shape Dell’s Austin plant and monitors from Sony’s manufacturing unit in Mexico matches them with the aid of client order and promises them to the clients.

This method permits Dell to save time and money associated with the greater handling of monitors.

Information flows in Supply Chain

The achievement of the Dell supply chain is facilitated through sophisticated information exchange. As a result of a complete study of a process view of the supply chain, Dell gives real-time records to suppliers at the current kingdom of demand.

Manufacturers are capable of getting entry to their components’ inventory tiers on the factories at the side of each day’s manufacturing necessities. Dell has created customized web pages so that its principal suppliers can view the call for forecasts and different purchaser-touchy statistics, accordingly helping suppliers to get a higher idea of consumer demand and better match their manufacturing schedules to that of Dell.

The Corporation has manufacturing concentrated in 5 manufacturing Centers-Brazil, China, Ireland, Malaysia, and Texas; because demand at every location is distinctly big and solid, suppliers are capable of top-off element inventories often, bearing in mind low degrees of stock inventories to be maintained.

In a few cases, Dell incorporates the most effective hours of element inventory at its factory. Dell’s low stage of stock additionally assists make certain that defects are not introduced into a huge amount of product.

While a new product is launched, Dell engineers are stationed right in the plant. If a consumer calls in with a hassle, production is stopped, and flaws are constant in actual time.

As there may be no finished product in stock, the quantity of faulty merchandise produced is minimized.

Dell also manages its cash flows very efficiently, via dealing with receivables and payables very carefully. They’re capable of gather cash from their customers, on common, ten to fifteen days earlier than they must pay their suppliers.

Understanding Supply Chain

Dell’s supply chain management cycle combines design and their management of the product, statistics, and cash flows play a vital function in the company’s achievement.

This technique has left Dell very well positioned in the computer enterprise. Given that PC is to an extent a commodity, the competitive battlefields more centered on supply chain flows responsiveness and performance. This bodes well for Dell.

This technique has left Dell very well positioned in the computer enterprise. Given that PC is to an extent a commodity, the competitive battlefields more centered on supply chain flows responsiveness and performance. This bodes well for Dell.

Key point

The importance of supply chain flows visible in any field of success in business. That’s why it’s very vital in the aspect of analytical as well as fundamental.