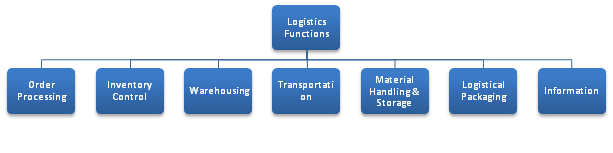

Logistics is a process of movement of goods across the supply chain of a company. However, this process consists of various functions that have to be properly managed to bring effectiveness and efficiency to the supply chain of the organization.

We will discuss the major functions of logistics here.

Read also: Concept of Logistics

Order processing

It is an important task in the functions of logistics operations. The purchase order placed by a buyer to a supplier is an important legal document of the transactions between the two parties.

This document incorporates the description or technical details of the product to supply, price, delivery period, payment terms, taxes, and other commercial terms as agreed.

The processing of this document is important as it has a direct relationship with the order or the performance cycle time, which indicates the time when the order is received and when the materials are received by the customer. The order processing activity consists of the following steps:

- Order checking for any deviations in agrees upon or negotiated terms

- Prices, payment, and delivery terms.

- Checking the availability of materials in stock.

- Production and material scheduling for shortages.

- Acknowledging the order indicating deviations if any.

Inventory control

Inventory management is to keep enough inventories to meet customer requirements, and simultaneously its carrying cost should be lowest.

It is basically an exercise of striking a balance between the customer service for not losing the market opportunity and the cost to meet the same.

The inventory is the greatest culprit in the overall supply chain of a firm because of its huge carrying cost, which indirectly eats away the profits. It consists of the cost of financing the inventory, insurance, storage, losses, damages, and pilferage.

The average cost of carrying inventory varies from 10 to 25 percent of the total inventory per year depending on the products.

Warehousing

Warehousing is the storing of finished goods until they are sold. It plays a vital role in logistics operations of a firm. The effectiveness of an organization’s marketing depends on the appropriate decision on warehousing.

In today’s context, warehousing is treated as switching facility rather than a storage of improper warehousing management. Warehousing is the key decision area in logistics.

The major decisions in warehousing are:

- Location of warehousing facilities

- Number of warehouses

- Size of the warehouse

- Warehouse layout

- Design of the building

- Ownership of the warehouse

Read also: Concept of warehouse

Transportation

For the movement of goods from the supplier to the buyer, transportation is the most fundamental and important component of logistics.

When an order is placed, the transaction is not completed till the goods are physically moved to the customer’s place. The physical movement of goods is through various transportation modes.

In logistics costs, its share varies from 65 to 70 percent in the case of mass-consumed, very low unit-priced products.

Firms choose the mode of transportation depending on the infrastructure of transportation in the country or region. Cost is the most important consideration in the selection of a particular mode of transport.

However, sometimes the urgency of the good at the customer end overrides the cost consideration. Because goods are sent through the fastest mode, which is an expensive alternative.

Read also: Basic cost elements in Transportation

Material handling and storage system

The speed of the inventory movement across the supply chain depends on the material handling methods. An improper method of material handling will add to the product damages and delays in deliveries and incidental overheads.

Mechanization and automation in material handling enhance the logistics system productivity.

Other considerations for selection of a material handling system are the volumes to be handled, the speed required for material movement and the level of service to be offered to the customer.

The storage system is important for maximum space utilization (floor and cubic) in the given size of a warehouse.

The material handling system should support the storage system for speedy movement (storage and retrieval) of goods in and out of the warehouse.

Logistical packaging

Logistical or industrial packaging is a critical element in the physical distribution of a product, which influences the efficiency of the logistical system. It differs from product packaging, which is based on marketing objectives.

However, logistical packaging plays an important role in damage protection, case in material handling and storage space economy. The utilization of load has a major bearing on logistical packaging with regard to the packaging cost.

Read also: Global Distribution

Information

Logistics is basically an information-based activity of inventory movement across a supply chain. Hence, an information system plays a vital role in delivering a superior service to the customers.

Use of IT tools for information identification, access, storage, analysis, retrieval and decision support which is vital among the functions of logistics is helping business firms to enhance their competitiveness.

Having a good logistics service improved customer service through shorter shipment times and flexibility to respond quickly to changing market trends, changing business environments.

Top logistics service provider in India

In responsive supply chain model quick customer service gets the highest priority where logistics service provider have important roles to play.

An availed logistics partner could really be of help on your forwarding endeavors. For they take care of your needs without hassling you unnecessary details but with an assurance of keeping in touch while the delivery is in process.

Dear Nancy,

Thanks for comment. Actually 3PL has important role in responsive model of supply chain.

The logistic function or logistic system is designed on the basis of the stated logistics objectives so that minimum cost would incur for the accomplishment of these objectives. The major functions of logistics will include Order Processing, Warehousing, Inventory Management and Transportation.

Warehouse is considered as an important link of logistic function which have significant impact on the flow of product. Any kind of accidents in the warehouse could slow down the product flow which ultimately affects the revenue. So, certain factors should be considered before choosing a warehouse. Location of the warehouse is one such important factor. Apart from this, the condition of different components of the warehouse should be inspected properly prior to choosing a warehouse for the storage of various commodities.

respected sir,

pls give me some important tips regarding the logistic & supply chain management.

with regards

sandip karan

8145013558

karan.sdandip04@gmail.com

Thanks for this platform but kindly i would request someone to send me on my email ” Roles of International Sourcing either in details or explained.’

Really knowlegeable indeed! and surely if at all one intended to vast his backround of logistics field as in backyard careere here we are!

surely very brief and solicited my mind towards my field work.

yours respectfully

Mohamed

very inspiring

Kindly help me with this question: Discuss the Total Cost Analysis in Managing the Logistics functions.

I have tried to answer it but my reasoning seems short of proper clarification. I badly need your help.

P.Mackina

+260 974053841

Dear Mackina,

Total cost incurs in Logistics functions involves all major functions such as transportation, warehousing, order processing, inventory carrying, etc.

Logistics should be treated as an integrated system because it involves several functions and the impact may adverse to other functions if you reduce cost in one function. So, better treat as a system while analyzing the cost.

We will write the detail of individual cost reduction and analysis for each function in the future post.

keep in touch.

I am carrying out a research study on Logistics function and the fast food industry, and I needed an assistant on the subject matter. Thanks!

please contact me directly: mukit.siddique@gmail.com

Please help me with this assignment.

Thanks

“Abu” Motors is an automotive firm who wants to develop a new model vehicle and requires the Logistic team liaise with the manufacturing sector in order to ensure efficient and effective management. One of the engineers has sent a request to you for an update on logistics operational functions.

As the head of the Logistics team respond to the request as required with emphases on ‘Logistics Management’.

Hi Great job putting this together! I question what AI will do in this space over the next five years.