If you want to measure supplier performance either in pre or post purchase, you have to consider some criteria. You can then give a weighted score during the evaluation period. Here I only list the assessment points during supplier capability measurement.

Quality capacity assessment

- Mission vision

- Investment in R&D

- Intellectual property

- Suppliers personnel

- Manufacturing capability and Technology

- Extent of previous experience with similar service

- Maintenance interval

- Durability.

Assess supplier motivation:

- participation in product design

- providing flexibility in specification

- arrange special quality content test or required inspection service

- engage special staff

capability measurement

- Mkt. Segments serviced by the supplier

- Not supplying competitors

- Capacity

- Subcontracts

- Stock limits

- Percentage of required item with supplier standard product range

- Export experience

- Supply horizon

- Delivery reliability

- Lead time

- Order treating system

- Assess logistics arrangements

- Security of supplier

- Technical

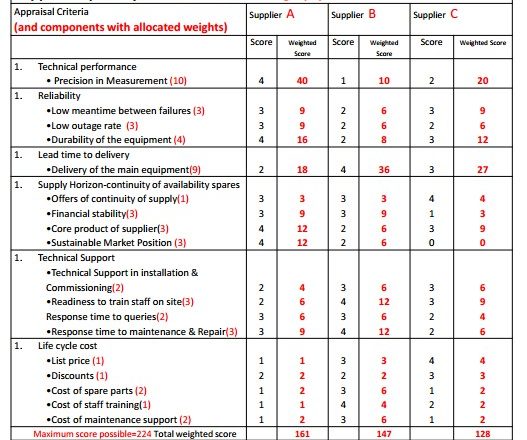

Reliability

- Low meantime between failures

- Low outrage rate

- Duration of service

- Lead time delivery

- Delivery of the main service

Supply Horizon

- Offer continuity of supply

- Financial Stability

- Core product of supplier

- Sustainable market position

Technical support

- Readiness to train staff on site

- Response time to queries

- Response time for maintenance & repair.

Performance Measurement and Evaluation

Post Purchase

A purchasing and supply chain performance evaluation system represents a formal, systematic approach to monitor and evaluate purchasing performance.

Problems with Purchasing Evaluation

- Too Much Data and Wrong Data Measures That Are Short-Term Focused Lack of Detail

- The type of errors that are occurring (wrong part picked, damage, shortages,

missed shipments, and so on) - Which customers are making the quality claims

- Which employees are responsible for the quality errors

- The total cost of the quality claims against the facility

- The part numbers that have quality claims against them

- Drive the Wrong Performance Measures of Behavior versus

Accomplishments

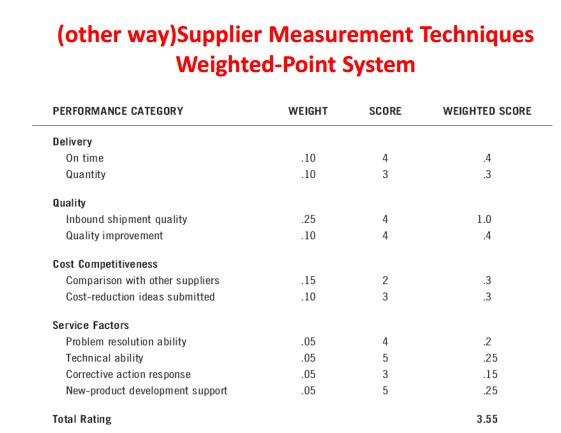

Purchasing and Supply Chain Performance Measurement Categories

- Price performance

- Cost-effectiveness

- Revenue

- Quality

- Time/delivery/responsiveness

- Technology or innovation

- Physical environment and safety

- Asset and integrated supply chain management

- Administration and efficiency

- Government and social

- Internal customer satisfaction

- Supplier performance

- Strategic performance

Develop Specific Performance Measures Developing a Performance Measurement

and Evaluation System

- Determine Which Performance Categories to Measure

- Use of Accurate and Available Data

- Creativity

- Directly Related to Organizational Objectives

- Joint Participation

- Dynamic over Time

- Non manipulable

- Establish Performance Objectives for Each Measure

- Historical Data

- Internal Comparisons

- External Analysis

- Finalize System Details

- Performance-Reporting Frequency

- Education and Training

- Using System Output

- Implement and Review System Performance and Measures

Hope you get the points mentioned above. If you want to add something don’t hesitate to comment here.

If you are in purchase or procurement department, you should know the supplier capability. So you have some experience based on your work.